Công ty TNHH Kỹ thuật Hàng hải Phương Đông là đại lý ủy quyền tại Việt Nam của TANKTECH CO., LTD trong cung cấp mới thiết bị, phụ tùng vật tư thay thế, dự trữ, lắp đặt, sửa chữa, bảo dưỡng, hiệu chuẩn định kỳ,.. cho các dòng sản phẩm như: thước đo hàng 3 chức năng – UTI (khoảng không, nhiệt độ, mặt phân cách dầu nước) dùng trên các tàu chở dầu, hóa chất, thước lấy mẫu hàng, van chặn hơi, đồng hồ đo áp suất khí trơ trong hầm hàng, sensor, dây thước, bo mạch điều khiển,…

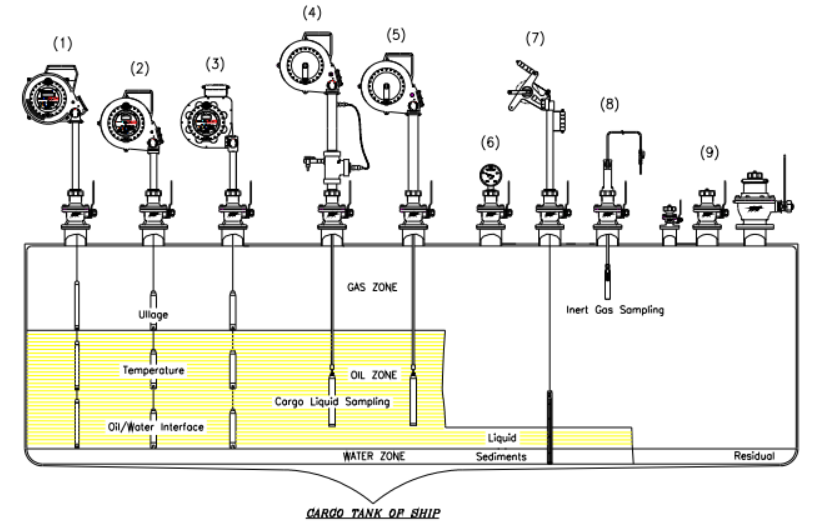

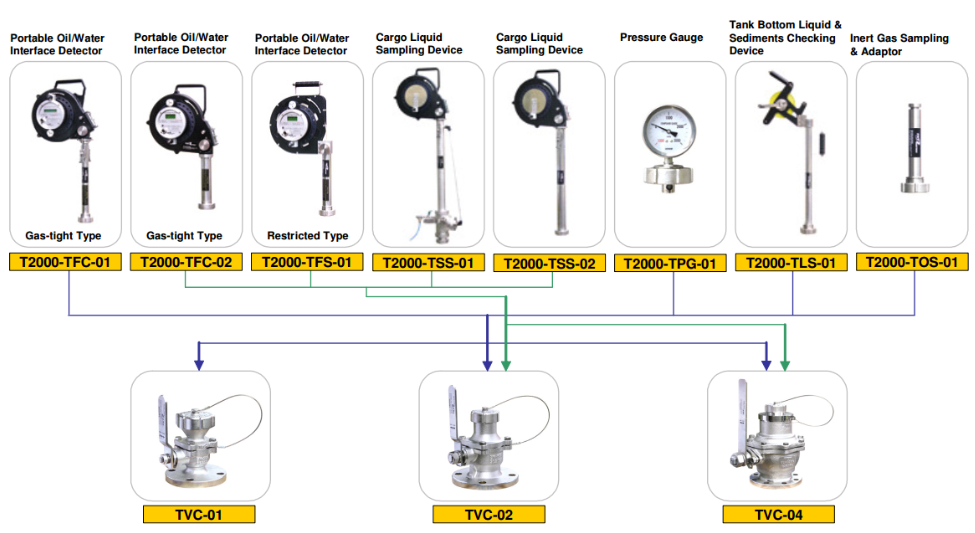

| No | Description |

| 1 |

Closed Type Portable Oil/ Water Interface Detector for Ullage, Oil/ Water Interface and Temperature gauging (Model: T2000-TFC-01) |

| 2 |

Closed Type Portable Oil/ Water Interface Detector for Ullage, Oil/ Water Interface and Temperature gauging (Model: T2000-TFC-02) |

| 3 |

Restricted type Portable Oil/ Water Interface Detector for Ullage, Oil/ Water Interface & Temperature gauging (Model: T2000-TFS-01) |

| 4 |

Gas Tight Type Cargo Liquid Sampling Device (Model: T2000-TSS-01) |

| 5 |

Closed Type Cargo Liquid Sampling Device (Model: T2000-TSS-02) |

| 6 |

Inert Gas Press Gauge (Model: T2000-TPG-01) |

| 7 |

Tank Bottom Dryness (Hand dipping), Checking Device (Model: T2000-TLS-01) |

| 8 |

Inert Gas Sampling Hose & Adaptor (Model: T2000-TOS-01) |

| 9 |

Shut On/ Off Valve (Vapor Control Valve) (Model: TVC-01, TVC-02, TVC-04) |

1. THƯỚC ĐO DẦU TANKTECH

Thước đo dầu TANKTECH có 3 chức năng chính là: đo khoảng không (Ullage), nhiệt độ (Temperature) và mặt phân cách dầu nước (Oily water interface). Thiết bị này đã qua kiểm tra và chứng nhận bởi các Cơ quan quản lý, thỏa mãn các yêu cầu của công ước SOLAS 1974 (Điều 60), bộ luật IBC BCH (Circ. 551), công ước MARPOL 73/78 (phục lục I, chương II), nghị quyết IMO MEPC. 5 (VIII)...

Ứng dụng: Thước đo dầu TANKTECH được sử dụng rộng rãi trên các tàu chở hóa chất, tàu chứa dầu thô, các sản phẩm xăng dầu, các tàu chứa ngoài khơi,…

- Thước đo dầu loại hạn chế (dùng cho tàu chở xăng dầu)

MODEL: T2000-TFS-01

- Đầu nối: PF 2 1/4"

- Chức năng: đo khoảng không (ULLAGE), nhiệt độ (Temperature), mặt phân cách dầu nước (Oil/ Water Interface)

- Độ chính xác, tin cậy cao

- Bảo vệ, chống ô nhiễm môi trường do dầu gây ra

- Kết cấu đơn giản, dễ sử dụng, bảo dưỡng

► Thông số kỹ thuật

- Độ chính xác trong đo Ullage và mặt phân cách dầu nước: +/- 2 mm

- Chỉ báo mức: Đọc và bằng âm thanh

- Chiều dài dây thước: 15/30/40 m

- Đơn vị đo: hệ mét

- Độ chia nhỏ nhất dây thước: 1mm

- Độ chính xác của dây thước: +/- 3.2 mm

- Đường kính đầu đo (sensor): 23 mm

- Chiều cao mức nhỏ nhất có thể đo: 10 mm

- Thang đo nhiệt độ của sensor: -20oC đến 110oC

- Độ phân giải của đầu đo nhiệt độ: 0.1oC

- Độ chính xác khi hiệu chuẩn: +/- 0.2oC (trong dãy từ 0oC đến 70oC)

- Đơn vị đo nhiệt độ: oC

- Màn hình hiển thị: LCD, 2 hàng, 16 ký tự

- Trọng lượng: 4.3 kg

- Kích thước: HxWxT = 645x315x150 mm

- Nguồn: pin 9V

- Cấp an toàn: Ex ia IIB T4

- Thước đo dầu loại kín (dùng cho tàu chở hóa chất)

| MODEL | T2000-TFC-01 | T2000-TFC-02 |

| DESC |

- Đầu nối: PF 2 1/4" - Chức năng: đo khoảng không (ULLAGE), nhiệt độ (Temperature), mặt phân cách dầu nước (Oil/ Water Interface) - Độ chính xác, tin cậy cao - Bảo vệ, chống ô nhiễm môi trường do dầu gây ra - Kết cấu đơn giản, dễ sử dụng, bảo dưỡng |

- Đầu nối: PF 2 1/4" - Chức năng: hiển thị cùng lúc trạng thái trong dầu, không khí, nước và nhiệt độ - Tính năng làm kín, chống rò lọt khí gây nguy hại ra ngoài - Một nút nguồn điều khiển On/Off duy nhất - Kết cấu đơn giản, dễ sử dụng, bảo dưỡng |

| TECH SPEC |

- Độ chính xác trong đo Ullage và mặt phân cách dầu nước: +/- 2 mm - Chỉ báo mức: Đọc và bằng âm thanh - Chiều dài dây thước: 15/30/40 m - Đơn vị đo: hệ mét - ĐCNN dây thước: 1mm - Độ chính xác của dây thước: +/- 3.2 mm - Đường kính đầu đo (sensor): 23 mm - Chiều cao mức nhỏ nhất có thể đo: 10 mm - Thang đo nhiệt độ của sensor: -20oC đến 110oC - Độ phân giải của đầu đo nhiệt độ: 0.1oC - Độ chính xác khi hiệu chuẩn: +/- 0.2oC (trong dãy từ 0oC đến 70oC) - Đơn vị đo nhiệt độ: oC - Màn hình hiển thị: LCD, 2 hàng, 16 ký tự - Trọng lượng: 4.3 kg - Kích thước: HxWxT = 645x315x150 mm - Nguồn: pin 9V - Cấp an toàn: Ex ia IIB T4 |

- Độ chính xác trong đo Ullage và mặt phân cách dầu nước: +/- 2 mm - Chỉ báo mức: Đọc và bằng âm thanh - Chiều dài dây thước: 15/30/40 m - Đơn vị đo: hệ mét - ĐCNN dây thước: 1mm - Độ chính xác của dây thước: +/- 3.2 mm - Đường kính đầu đo (sensor): 34 mm - Chiều cao mức nhỏ nhất có thể đo: 8 mm - Thang đo nhiệt độ của sensor: -20oC đến 110oC - Độ phân giải của đầu đo nhiệt độ: 0.1oC - Độ chính xác khi hiệu chuẩn: +/- 0.1oC (trong dãy từ 0oC đến 60oC) - Đơn vị đo nhiệt độ: oC - Màn hình hiển thị: LCD, 4-7 ký tự - Trọng lượng: 8.1 kg (30M) - Kích thước: HxWxT = 585x346x150 mm - Nguồn: pin 9V - Cấp an toàn: Ex ia IIB T4 |

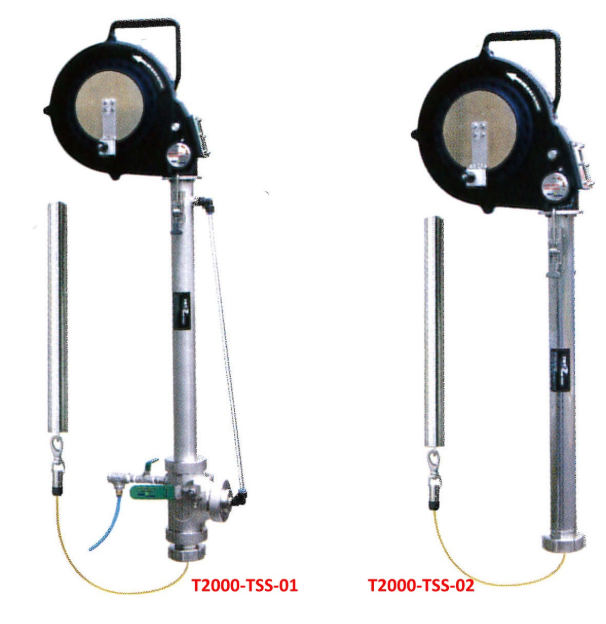

2. THƯỚC LẤY MẪU TANKTECH

Thước lấy mẫu TANKTECH dùng để lấy mẫu hàng hóa chứa trong các két trên các tàu chứa hàng lỏng xô, không làm rò lọt khí từ bên trong hầm hàng ra môi trường bên ngoài, tránh làm thất thoát bay hơi hàng hóa hay rò lọt khí nguy hiểm ra môi trường

Ứng dụng: thước lấy mẫu TANKTECH được sử dụng rộng rãi trên các tàu chở hóa chất, tàu chứa dầu thô, các sản phẩm xăng dầu,...

- Thước lấy mẫu loại hạn chế (dùng cho tàu chở xăng dầu)

MODEL: T2000-TSS-02

- Chiều dài dây thước: 15/30/40 m

- Đơn vị đo: hệ mét

- ĐCNN dây thước: 1 mm

- Độ chính xác của dây thước: +/- 3.2 mm

- Đầu nối: PF 2 - 1/4"

- Trọng lượng: 8.95 kg

- Kích thước: HxWxT = 870 x 346 x 199 mm

- Dung tích lọ đựng mẫu: 0.5 và 1 lít

- Thước lấy mẫu loại kín (dùng cho tàu chở hóa chất)

MODEL: T2000-TSS-01

- Chiều dài dây thước: 15/30/40 m

- Đơn vị đo: hệ mét

- ĐCNN dây thước: 1 mm

- Độ chính xác của dây thước: +/- 3.2 mm

- Đầu nối: PF 2 - 1/4"

- Trọng lượng: 10.75 kg

- Kích thước: HxWxT = 1010 x 346 x 199 mm

- Dung tích lọ đựng mẫu: 0.5 lít

3. THƯỚC KIỂM TRA KHÔ SẠCH KÉT HÀNG TÀU DẦU/ HOÁT CHẤT

MODEL: T2000-TLS-01

- Chiều dài dây thước: 50m

- Đơn vị đo: hệ mét

- Độ chia nhỏ nhất dây thước: 1mm

- Đầu nối: PF 2 - 1/4"

- Trọng lượng: 3.8 kg

- Kích thước: HxWxT = 800 x 310 x 90 mm

4. ĐỒNG HỒ ĐO ÁP SUẤT KHÍ TRƠ

MODEL: T2000-TPG-01

- Dùng kèm với van chặn TVC-02

- Thang đo: từ -1000 đến 3000 mm H2O

- Độ chính xác: 1.5% toàn thang

- Đầu nối: PF 2 - 1/4"

5. DÂY LẤY MẪU KHÍ TRƠ TRONG HẦM HÀNG

MODEL: T2000-TOS-01

- Đường kính ống: 8 (đường kính ngoài)/ 6 (đường kính trong)

- Chiều dài ống: 35 mm

- Đầu nối: PF 2 - 1/4" (dùng kèm với van chặn TVC-02)

6. VAN CHẶN HƠI

| MOD | TVC-01 | TVC-02 | TVC-04 |

| Desc |

- Loại: van bi - Đường kính viên bi: 1” (25 mm) - Mặt bích nối: 50A JIS 5K F.F - Đầu nối phía trên: PF 2 - 1/4" - Khối lượng: 3 kg |

- Loại: van bi - Đường kính viên bi: 2” (50 mm) - Mặt bích nối: 80A hoặc 50A JIS 5K F.F - Đầu nối phía trên: PF 2 - 1/4" - Khối lượng: 7.6 kg |

- Loại: van bi - Đường kính viên bi: 4” (100 mm) - Mặt bích nối: 100A JIS 5K F.F - Đầu nối phía trên: + Cho thước đo hàng: PF 2 - 1/4" + Cho thước lấy mẫu: M1118 x P1.5 - Khối lượng: 13.6 kg |

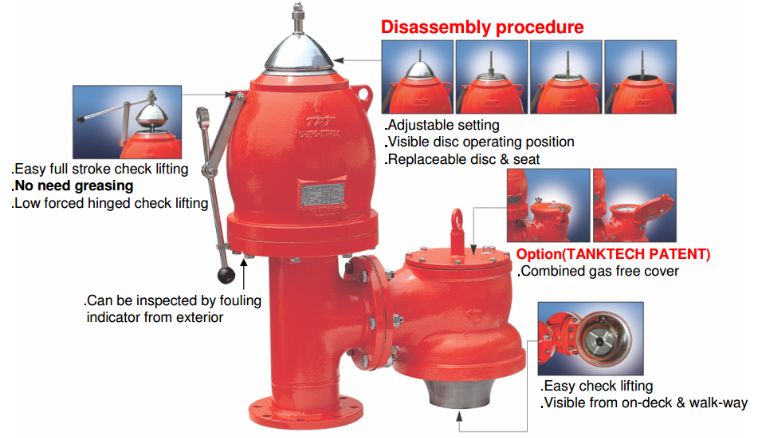

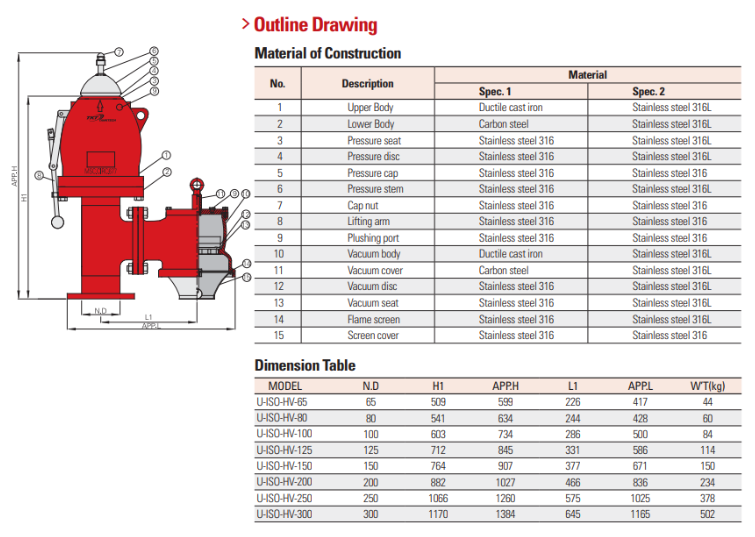

7. VAN AN TOÀN

Công ty TNHH Kỹ thuật Hàng hải Phương Đông là đại lý ủy quyền tại Việt Nam của TANKTECH CO., LTD trong cung cấp mới thiết bị, phụ tùng vật tư thay thế, dự trữ, lắp đặt, sửa chữa, bảo dưỡng, hiệu chuẩn định kỳ,.. cho các dòng sản phẩm như: van an toàn két hàng, máy rửa vệ sinh két hàng, máy rửa vệ sinh bồn bể, sung phun nước chống cướp biển, hệ thống chống nghiêng cho tàu, hệ thống chữa cháy phun sương nước, nắp hầm hàng, cầu chằng buộc chuyên dùng cho tàu container, thiết bị kéo tàu khẩn cấp….

Van an toàn két hàng TANKTECH được thiết kế giúp ngăn chặn ngọn lửa lan vào bên trong két hàng, xả áp lực quá cao bên trong hầm hàng ra ngoài hoặc phá bỏ áp suất chân không của hàng hóa trong suốt quá trình xếp hàng, trả hàng, bơm ballast hay có sự thay đổi về yếu tố nhiệt

Ứng dụng: van an toàn két hàng TANKTECH được sử dụng rộng rãi trên các tàu chở hóa chất, tàu chứa dầu thô, các sản phẩm xăng dầu, các tàu chứa ngoài khơi…

► Thỏa mãn các qui định:

- IMO MSC/Circ. 677/1009, ISO 15364:2007, ISO16852:2010

- IMO MSC/Circ.450 Rev.1

- IMO MSC/Circ.585

- IMO MSC/Circ.731

- API 2000 - Flow test procedure

- Vapor control system of USCG ( 46 CFR.39-20.11 & 162.017 )

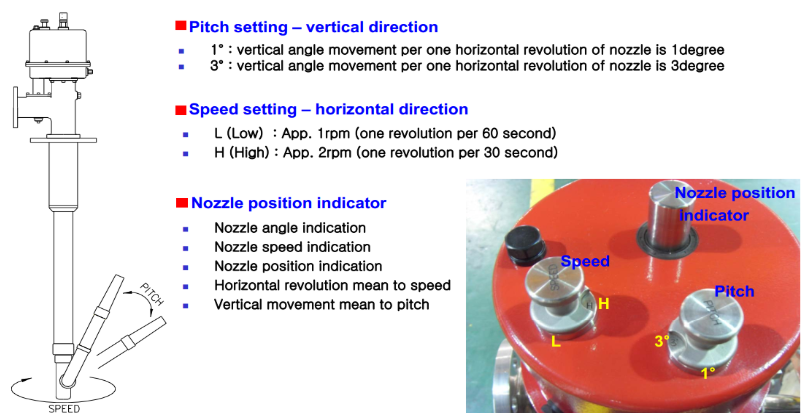

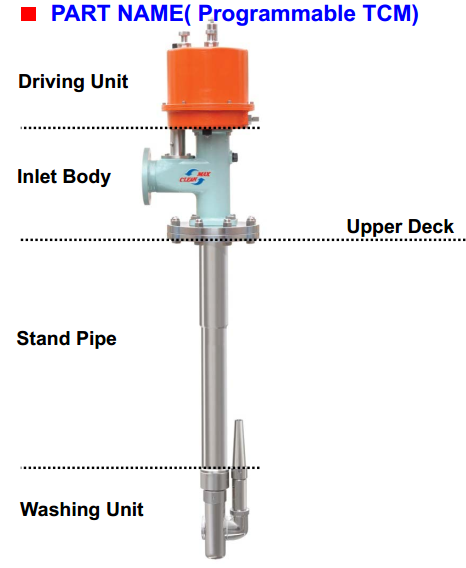

8. MÁY RỬA VỆ SINH KÉT HÀNG TÀU DẦU

Máy rửa vệ sinh két hàng tàu dầu TANKTECH được lắp đặt trên miệng két hoặc trên mặt boong của các tàu chở dầu và hóa chất, giúp vệ sinh két, đáp ứng các yêu cầu của IMO Resolution A.897(21). Với thiết kế một đầu phun cải tiến, nhiều ưu điểm hơn so với loại đầu phun kép, giúp tiết kiệm khi bơm, vét cùng chiều xa phun hiệu quả hơn

Ứng dụng: Máy rửa vệ sinh két hàng tàu dầu TANKTECH được sử dụng rộng rãi trên các tàu chở hóa chất, tàu chứa dầu thô, các sản phẩm xăng dầu, các tàu chứa ngoài khơi…

► Với các đặc điểm:

- Quay ngang 360o

- Chuyển động đứng: 25 – 155o

- Bước chuyển động đứng: 1o và 3o

- Khả năng điều chỉnh tốc độ: thấp/ cao

- Khả năng làm việc một hoặc nhiều trạng thái ở bất kỳ dãy góc làm việc nào mong muốn

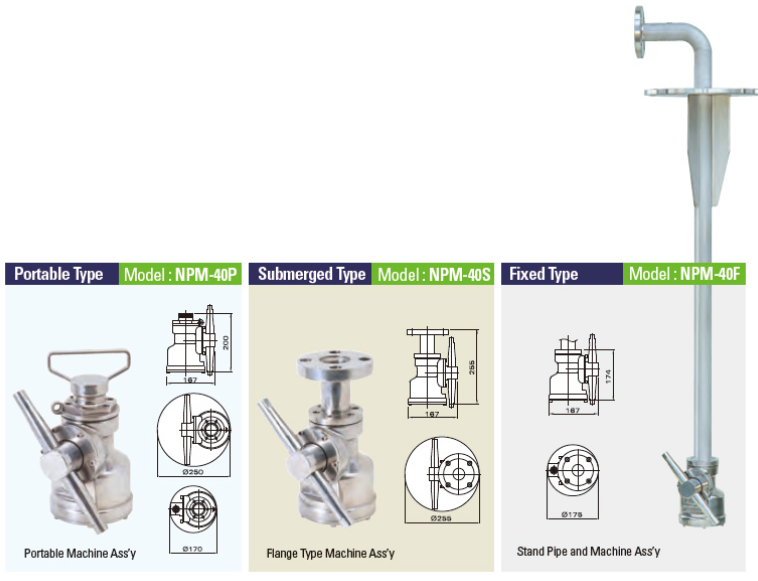

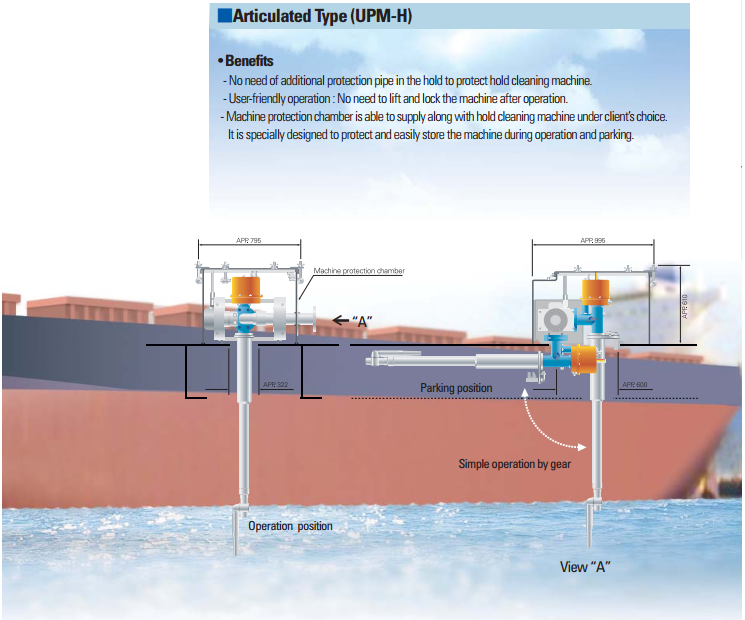

9. MÁY RỬA VỆ SINH HẦM HÀNG TÀU HÀNG

Máy rửa vệ sinh hầm hàng tàu hàng TANKTECH được lắp đặt trên miệng hầm hàng hoặc mặt boong của các tàu chở hàng rời, bách hóa tổng hợp, giúp vệ sinh sạch sẽ hầm hàng trước khi tiến hành xếp hàng mới, khác loại xuống hầm hàng, tránh làm nhiễm bẩn hoặc hư hỏng cho hàng hóa mới

Ứng dụng: máy rửa vệ sinh hầm hàng tàu hàng TANKTECH được sử dụng rộng rãi trên các tàu chở hàng rời, bách hóa tổng hợp,…

► Ưu điểm:

- Không cần bố trí thêm ống bảo vệ cho thiết bị trong hầm hàng

- Điều khiển dễ dàng, không cần nâng hoặc khóa thiết bị sau khi sử dụng

- Buồng bảo vệ thiết bị có thể bố trí dọc theo máy

- Sử dụng nước biển kết hợp với bơm nước biển và van thông biển. Đồng thời sử dụng nước ngọt từ két sau lái để vệ sinh tráng lại

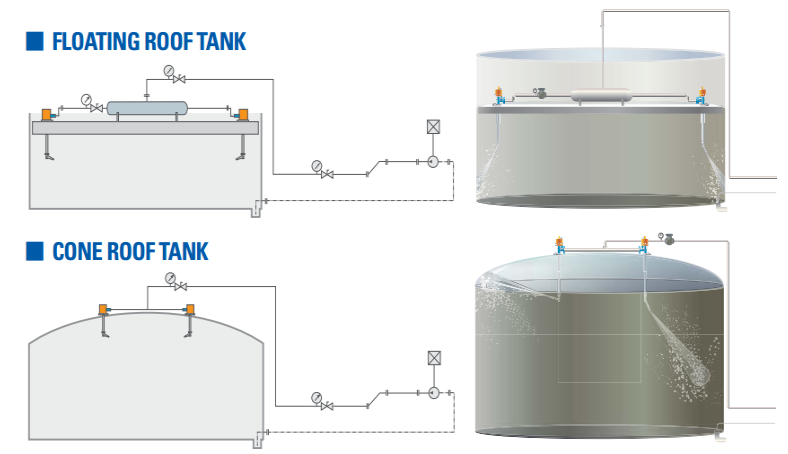

10. MÁY RỬA VỆ SINH BỒN CHỨA XĂNG DẦU, HÓA CHẤT

Máy rửa vệ sinh bồn chứa xăng dầu, hóa chất TANKTECH được lắp đặt trên miệng các bồn chứa dầu thô và sản phẩm xăng dầu khác, giúp vệ sinh sạch sẽ bồn chứa trước khi nhận một loại hàng khác

Ứng dụng: Máy rửa vệ sinh bồn chứa xăng dầu, hóa chất TANKTECH được sử dụng rộng rãi trên các bồn chứa tại các kho xăng dầu, nhà máy lọc dầu,..

► Ưu điểm:

- Thiết bị tự động làm sạch bồn chứa

- Không cần phải chờ thời gian thông gió (gas free) bồn chứa

- Dễ dàng làm sạch hỗn hợp dầu và cặn bẩn

- Dễ sử dụng, bảo dưỡng và giám sát làm việc

- Thiết kế nhỏ gọn

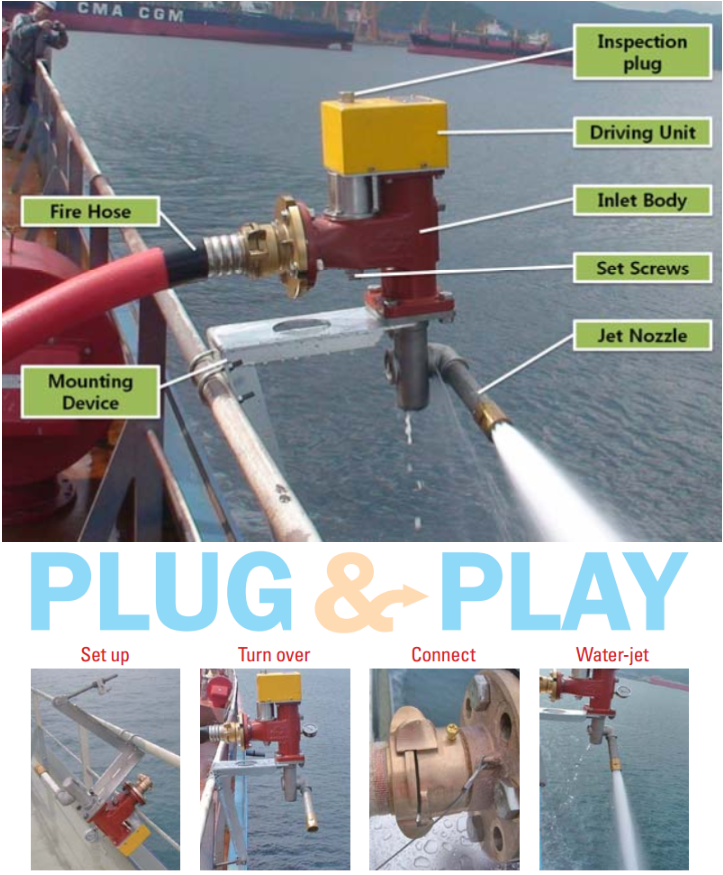

11. SÚNG PHUN NƯỚC CHỐNG CƯỚP BIỂN

Súng phun nước chống cướp biển TANKTECH là hệ thống phun nước giúp đề phòng hải tặc lên tàu. Hệ thống bao gồm các đầu phun nước được lắp đặt bên mạn tàu, góc quay 150o, phun nước áp lực cao liên tục, có thể được lắp đặt trên bất kỳ loại tàu nào, đặc biệt an toàn và thích hợp đối với các loại tàu chở dầu, hóa chất, khí gas LPG, LNG,…

► Ưu điểm:

- Sử dụng nước áp lực cao, không gây chết người

- Chỉ nối và dùng (Plug and Play), không yêu cầu lắp đặt thêm bất kỳ thiết bị nào khác

- Thiết bị làm việc không cần người vận hành và không yêu cầu bảo dưỡng

- Đảm bảo an toàn, phù hợp với tất cả mọi loại tàu

- Công suất cao, ít hao nước

- Phun xa 38m, lưu lượng 26 m3/h ở áp suất 8 bar

Trân trọng!

Công ty TNHH Kỹ thuật Hàng hải Phương Đông

+84 903 751396

+84 903 751396 phuongdong@otm.vn

phuongdong@otm.vn