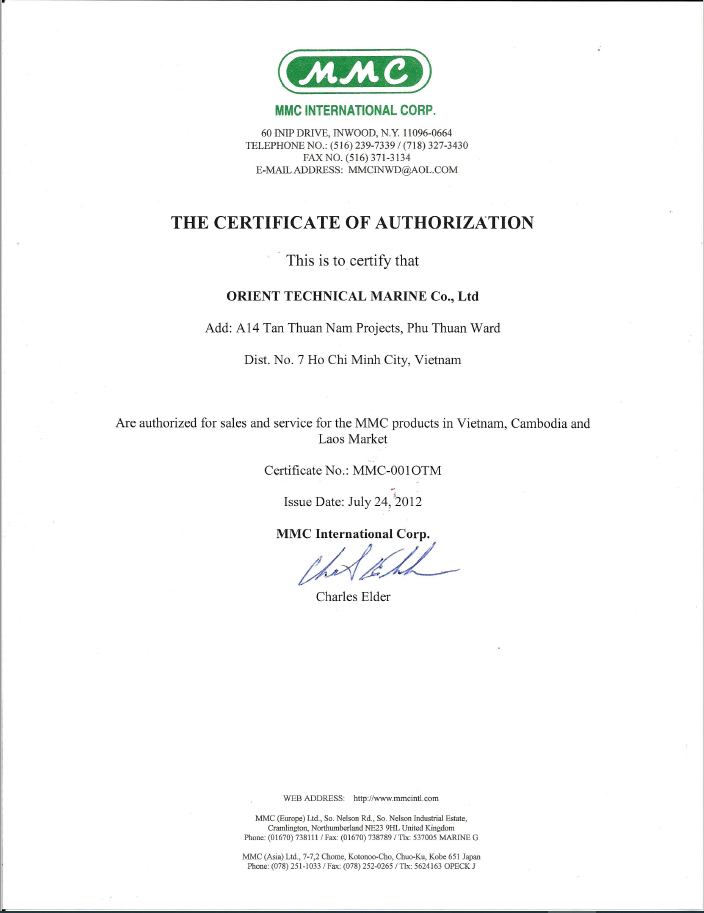

Công ty TNHH Kỹ thuật Hàng hải Phương Đông là đại lý ủy quyền tại Việt Nam của MMC INTERNATIONAL CORPORATION trong cung cấp mới thiết bị, phụ tùng, vật tư thay thế sửa chữa, bảo dưỡng, hiệu chuẩn định kỳ cho các dòng sản phẩm như: Thước đo hàng 3 chức năng (khoảng không, nhiệt độ, mặt phân cách dầu nước) dùng trên các tàu chở dầu, hóa chất, thước lấy mẫu hàng, van chặn hơi, đồng hồ đo áp suất khí trơ trong hầm hàng, sensor, dây thước, bo mạch điều khiển…

1. Thước đo dầu MMC (Asia), Model D-2401-2

Thước đo dầu MMC (Asia) model D-2401-2 có 3 chức năng chính là đo khoảng không, nhiệt độ và mặt phân cách dầu nước (chủ yếu trên các tàu chở hàng lỏng). Thiết bị thước đo két di động này thuộc loại thiết bị an toàn, đã qua kiểm tra và chứng nhận bởi các Cơ quan quản lý , thỏa mãn yêu cầu của nghị quyết MEPC 5(XIII) đối với thiết bị kiểm tra mặt phân cách dầu nước

Kết cấu thước bao gồm: dây thước dẫn tín hiệu, đầu cảm biến âm thanh 3 chức năng và bo mạch điều khiển (sử dụng pin) bố trí bên trong thân thước (gồm cụm rulo quay thước và ống bảo vệ đầu sensor). Thước dùng để đo mức khoảng không, mặt phân cách dầu nước và nhiệt độ của hàng hóa dạng lỏng chứa bên trong két kín hoặc hạn chế (không thông với môi trường khí quyển) một cách dễ dàng, trực tiếp, chính xác và an toàn thông qua các van chặn lắp đặt cố định trên mặt boong của các tàu chở dầu

2. Thước đo dầu MMC (USA), Model D-2401-2

- Thước đo dầu ba chức năng loại kín (CLOSED)

Thước đo dầu MMC (USA) model D-2401-2 thuộc loại kín hoàn toàn, dùng bộ điều khiển điện tử với nguồn năng lượng cấp từ pin. Khi lắp thước vào van chặn trên ống đo của các két hàng hóa, nó tạo thành một hệ thống kín hoàn toàn, giúp ngăn chặn hơi độc của hàng hóa thoát ra khỏi két. Đơn vị đo trên dây thước thể hiện bằng hệ mét hoặc hệ inch và được bọc lớp chống nhiễu (tín hiệu cảm biến). Ngoài ra thước còn được đánh dấu bằng màu sắc để chỉ hướng quay, giúp dễ dàng quan sát khi thước chuyển động đến vị trí thu thước hoàn toàn. Thước được trang bị dây tiếp mát với đầu kẹp lớn. Thiết bị này tương đương như một hệ thống đo lắp đặt cố định do thước vẫn có thể giữ nguyên ở vị trí nối với van trên ống đo của két chứa từ khi bắt đầu cho đến khi kết thúc việc bơm nhận hoặc trả hàng

► Thông số kỹ thuật:

- Độ chính xác:

+ Mức chất lỏng: +/- 1/8 inch (3 mm), +/- 0.101% toàn thang đo

+ Nhiệt độ: +/- 0.5oF (+/- 0.2oC), sai số +/-1 digit

- Giới hạn nhiệt độ môi trường: -20°F (-7°C) đến 120°F (49°C)

- Giới hạn nhiệt độ hàng hóa đo: -40°F (-40°C) đến 190°F (88°C)

- Nguồn: pin 9 Volt, loại Duracell MN1604

- Chiều dài dây thước: 50ft. (15m), 65 ft. (20m), 75 ft. (25m), 100 ft. (30m)

- Khối lượng: 14 lbs. (6.4 kg)

- Giới hạn áp suất:

+ Áp suất làm việc: 3 psi

+ Áp suất tối đa: 7.5 psi

- Cơ quan chứng nhận an toàn: FM, BASEEFA, CSA, NKK (Japan)

- Thước đo dầu ba chức năng loại giới hạn hoặc hở (OPEN)

Thước loại giới hạn hoặc hở có ưu điểm thuận tiện và chính xác trong đo mức khoảng không, nhiệt độ hàng hóa và mặt phân cách dầu nước. Thước có thể làm việc ở chế độ 3 chức năng, 2 chức năng hoặc chỉ để đo nhiệt độ. Khi đầu cảm biến tiếp xúc với thành phần hydrocacbon, thước sẽ phát ra âm thanh kêu liên tục, khi tiếp xúc với nước thước sẽ phát ra âm thanh kêu ngắt quãng. Nhiệt độ đo được hiển thị trên màn hình LED gắn trên rulo quay của thước.

► Thông số kỹ thuật:

- Độ chính xác:

+ Mức chất lỏng: +/- 1/8 inch (3mm), +/- 0.01% toàn thang đo

+ Nhiệt độ: +/- 0.5oF (+/- 0.2oC), sai số +/-1 digit

+ Dãy nhiệt độ hiệu chuẩn: từ 32oF (0oC) đến 176oF (88oC)

+ Đầu sensor: cách đáy khô sạch 3/8 inch (10 mm)

- Giới hạn nhiệt độ môi trường: -20oF (-7oC) đến 120oF (49oC)

- Giới hạn nhiệt độ hàng hóa đo: -40oF (-40oC) đến 190oF (88oC)

- Ứng dụng:

+ Đo hở (Loại “O”- thông với môi trường): dùng với loại hàng hóa pha hơi đảm bào an toàn

+ Đo giới hạn (Loại “R”- giới hạn thông với môi trường): dung kèm với van chặn của MMC

- Nguồn; Pin 9 volt, loại Duracell MN1604

- Chiều dài dây thước:

+ Một mặt: 50ft (15m), 65ft (20m), 75ft (25m), 100ft (30m)

+ Một mặt: đặc biệt thang kỹ thuật 100ft

- Khối lượng:

+ 50ft/15m – “R” 8 lbs (3.6 kg), “F” 7 lbs (3.2 kg)

+ 100ft/30m - “R” 9 lbs (4.1 kg), “F” 8 lbs (3.6 kg)

- Cơ quan chứng nhận an toàn: FM, BASEEFA, CSA, NKK (Japan), ATEX (SIRA)

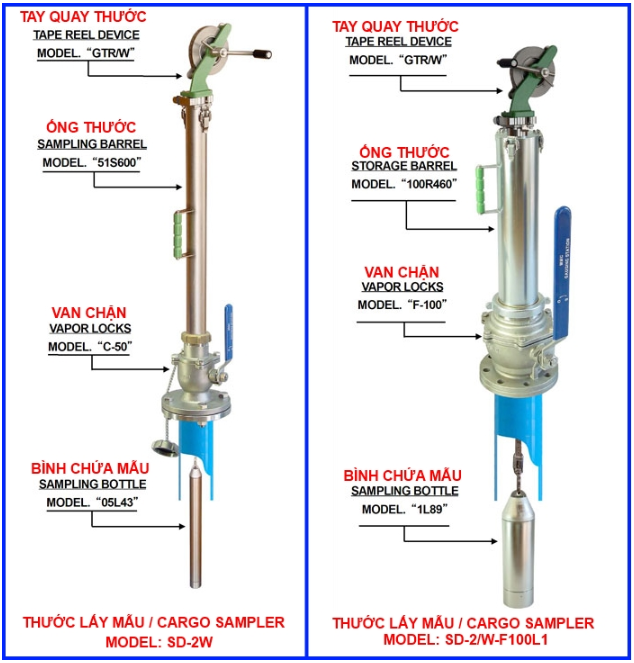

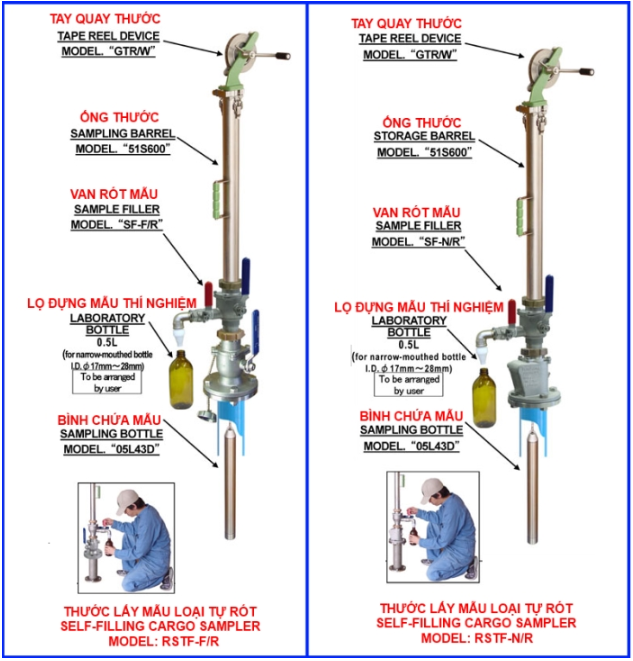

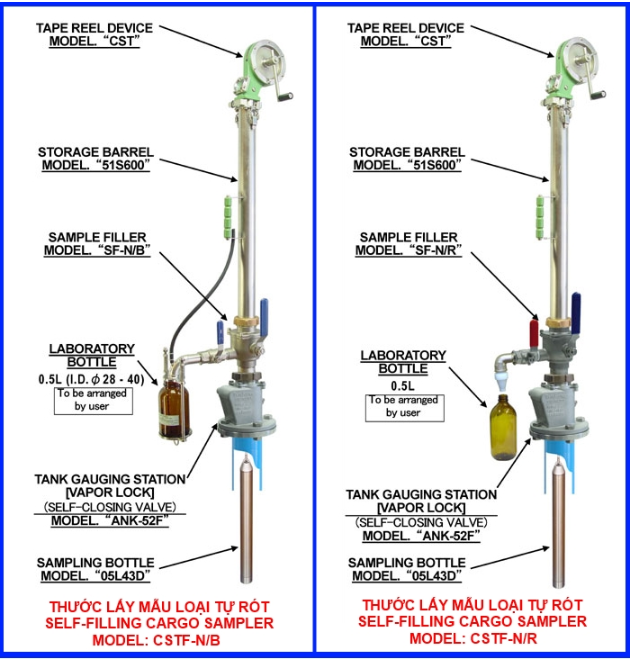

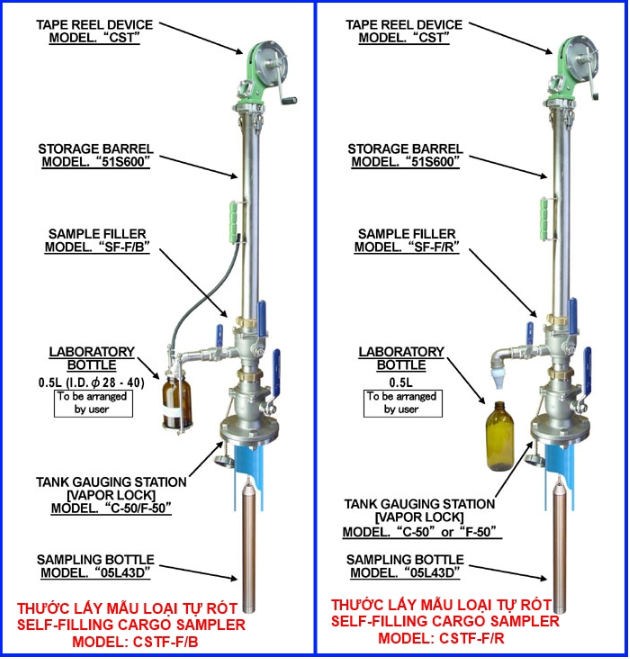

3. Thước lấy mẫu MMC (Asia)

Theo tiêu chuẩn an toàn về thiết bị đo hàng và lấy mẫu, cần thiết ngăn chặn hoặc giới hạn sự rò rỉ hơi hàng hóa thoát khỏi két chứa trong suốt quá trình đo đạc hoặc lấy mẫu. Vì vậy, sử dụng thước lấy mẫu di động MMC gắn vào van chặn được lắp đặt cố định sẵn trên tàu, sẽ ngăn chặn hiện tượng phóng tĩnh điện, đảm bảo an toàn trong quá trình lấy mẫu, không làm thoát hơi hàng hóa nguy hiểm bên trong két chứa ra môi trường bên ngoài

- Thước lấy mẫu kiểu giới hạn (dùng trên các tàu chở dầu)

| SAMPLING CAPACITY | MODEL No of EQUIPMENT | TYPE of VAPOR LOCKS to be mounted |

| 0.5 liter | SD-2/W | C-50/ F-50 |

| 1 or 2 liter |

SD-2/W-F100L1 SD-2/W-F100L2 |

F-100 |

| 0.5 liter | RSTF-F/R | C-50/ F-50 |

| 0.5 liter | RSTF-N/R | ANK-52/ ANK-52F |

- Thước lấy mẫu kiểu kín (dùng trên các tàu chở dung môi hóa chất)

| SAMPLING CAPACITY | MODEL No of EQUIPMENT | TYPE of VAPOR LOCKS to be mounted |

| 0.5 liter | CSTF-F/B | C-50/ F-50 |

| 0.5 liter | CSTF-F/R | C-50/ F-50 |

| 0.5 liter | CSTF-N/B | ANK-52/ ANK-52F |

| 0.5 liter | CSTF-N/R | ANK-52/ ANK-52F |

4. Thước lấy mẫu MMC (USA)

- Thước lấy mẫu loại kín (CLOSED)

Được thiết kế thích hợp với hầu hết các loại van chặn của MMC như van loại B, MB, MMB và F/C50, chuyên dùng ở các khu vực nghiêm cấm sự bay hơi của hàng hóa trong két ra môi trường bên ngoài khi tiến hành đo hàng hoặc lấy mẫu bên trong két. Khi lắp thước vào van chặn MMC trên các ống đo hoặc ống lấy mẫu, ta có thể tiến hành lấy mẫu bên trong két, sau đó đóng van, tháo thước ra khỏi van và trút mẫu vào bình chứa. Có thể chuyển thước sang chức năng đo mức hoặc kiểm tra tình trạng khô sạch của két của két chứa bằng cách gắn quả dọi vào dây thước.

► Thông số kỹ thuật:

- Độ chính xác của dây thước: +/- 1/8inch (3mm), +/- 0.01% toàn thang đo

- Chiều dài dây thước:

+ Dây inox: 50 ft. (15m), 75 ft. (25m), 100 ft. (30m), 120 ft. (37m)

+ Dây phủ Tefzel trơ hóa: đến 30m, dùng cho két chứa dung môi hóa chất

- Khối lượng: 14 lbs. (6.4 kg)

- Giới hạn áp suất:

+ Áp suất làm việc: 3 psi

+ Áp suất tối đa: 7.5 psi

- Thước lấy mẫu loại giới hạn (RESTRICTED)

Được thiết kế thích hợp với hầu hết các loại van chặn MMC. Mỗi thước lấy mẫu bao gồm dây thước có móc phía đầu, bình lấy mẫu ½ lít, và quả dọi bằng đồng theo tiêu chuẩn API.

Thước chuyên dùng để lấy mẫu bằng tay, đo mức hoặc kiểm tra tình trạng khô sạch của két chứa. Tương tự như thước lấy mẫu loại kín, thước lấy mẫu loại giới hạn có thể lắp sử dụng được hết với các loại van chặn MMC, tiến hành lấy mẫu bên trong két, sau đó đóng van, tháo thước ra khỏi van và dùng tay trút mẫu vào bình chứa. Có thể chuyển thước sang chức năng đo mức hoặc kiểm tra tình trạng khô sạch của két chứa bằng cách gắn quả dọi vào đầu dây thước

► Thông số kỹ thuật:

- Độ chính xác của dây thước: +/- 1/8inch (3mm), +/- 0.01% toàn thang đo

- Ứng dụng: lấy mẫu giới hạn “R”, với bình lấy mẫu loại 1, 1/2 và 1/3 lít khi lắp thước vào van chặn MMC

- Chiều dài dây thước:

+ Dây inox bọc nhựa: 50 ft./15m, 75 ft./22.5m, 100 ft./30m, 120 ft./37m

- Khối lượng (không bao gồm bình chứa mẫu)

+ Loại 100 ft./30m(dùng với bình chứa mẫu 1 lít): 9 lbs. (4.1 kg)

+ Loại 100 ft./30m(dùng với bình chứa mẫu 1/2 lít): 10 lbs. (4.5 kg)

- Khối lượng thông thường: 14 lbs. (6.4 kg)

- Giới hạn áp suất:

+ Áp suất làm việc: 3 psi

+ Áp suất tối đa: 7.5 psi

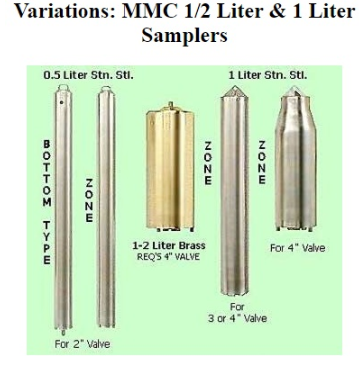

- BÌNH CHỨA MẪU

- Vật liệu chế tạo bằng inox (có thể bằng đồng)

+ Loại bình 1 lít: D x L = 3.5" x 10", dùng cho van cỡ "S", 4" [Model 1LTR-3.5X10LG]

+ Loại bình 1 lít: D x L = 2.5" x 16", dùng cho van cỡ "MBS-3", 3" [Model 1LTR-2.5X16LG]

+ Loại bình 1/2 lít: D x L = 1.625" x 18", dùng cho tất cả các van cỡ 2" [Model 1/2LTR-1.625X18]

+ Loại bình 1/3 lít: D x L = 1.375" x 28", dùng cho các van cỡ “MMB”, 1/2" [Model 1/2LTR-1.375X28]

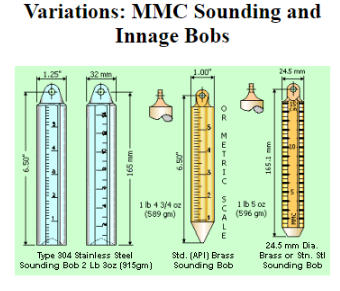

- QUẢ DỌI

- Là vật tư đi kèm với thước, loại quả dọi bằng đồng 6”. Có thể yêu cầu loại quả dọi bằng inox. Quả dọi bằng đồng dùng để đo mức, có thể yêu cầu thang đo hệ mét hoặc inch.

- Nếu dùng để kiểm tra khô sạch két, gắn với van 1”, quả dọi bằng đồng 24.5mm có thể yêu cầu như một vật tư đặt hàng riêng

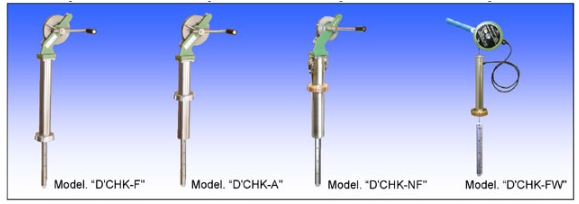

5. Thước kiểm tra khô sạch két MMC (Asia)

Theo qui định của tổ chức hàng hải quốc tế IMO về ngăn ngừa ô nhiễm và an toàn tàu dầu 1978, đối với chức năng của hệ thống bơm vét, đo mức và kiểm tra khô sạch két, tàu phải được trang bị phương tiện để kiểm tra khô sạch của két hàng sau khi tiến hành vệ sinh két. Việc bố trí thiết bị phải phù hợp để kiểm tra bằng tay ở vị trí sau lái trong két hàng và ở 3 vị trí phù hợp khác, trừ khi có thiết bị được chấp nhận lắp đặt để kiểm tra hiệu quả sự khô sạch bên trong két chứa. Do đó, biện pháp đơn giản nhất để kiểm tra tình trạng khô sạch của két chứa là sử dụng một dây thước bằng thép không gỉ, có đầu quả năng bằng cách quay rulo cho thước chạm đáy két và đọc mức dầu còn lại trên dây thước.

Thước kiểm tra khô sạch két được gắn vào van chặn hơi nhằm đảm bảo hạn chế sự rò rỉ của khí trơ bên trong hầm hàng thoát ra ngoài và tiếp mát, đảm bảo khả năng chống cháy nổ do sự tích tĩnh điện sau khi tiến hành vệ sinh két chứa hàng

- Model. "D'CHK-F": thích hợp dùng với các van chặn loại "C-50", "F-100" & "D-25"

- Model. "D'CHK-A": thích hợp dùng với các van chặn loại "G65K80" & "A"

- Model. "D'CHK-NF": thích hợp dùng với các van chặn loại "ANK-52" & "ANK-52F"

- Model. "D'CHK-FW": thích hợp dùng với các van chặn loại "C-50", "F-100" & "D-25"

6. Van chặn hơi (Vapor Control Valve)

Van chặn hơi dùng cho việc đo mức hoặc lấy mẫu hàng hóa là sản phẩm xăng dầu, hóa chất chứa bên trong két

Seri “B”: van B đường kính 2” (50mm), micro B đường kính 2” (50mm), và Mini micro B đường kính 1-1/2" (38mm)

Thích hợp sử dụng cho việc cách ly két, van chặn MMC B là thiết bị ngắt chủ động, hỗ trợ cho các thước đo mức 3 chức năng (đo khoảng không, mặt phân cách và nhiệt độ, cũng như các thước đo mức O2 trong két chứa. Loại này có 3 model (đường king trong bằng 2”): B, Micro B và F50. Loại van Mini micro B có đường kính là 1-1/2”. Tất cả đều là kiểu van bi có Teflon làm kín, có mặt bích giúp dễ lắp đặt và định vị chính xác, vật liệu chế tạo bằng thép không gỉ, nắp bằng đồng. Tất cả các thước đo hàng MMC đều có thể gắn trực tiếp với các van chặn hơi

► Thông số kỹ thuật:

- Vật liệu chế tạo: bằng thép không gỉ 316, nắp bằng đồng, seal làm kín bằng Teflon hoặc Viton ®

- Kích thước mặt bích lắp đặt:

+ Van "B”, 2" (2318-2S-F316-BC): đường kính ngoài 6" (152), đường kính vòng tròn tâm lỗ bulon 4 3/4" (121), đường kính lỗ bulon (4 lỗ) 3/4" (19)

+ Van Micro "B", 2" (2318-2S-FMS-BC): đường kính lỗ bulon (4 lỗ) 3/4" (19)

+ Van Mini Micro "B", 1 1/2" (2318-2S-F316BC): đường kính ngoài 5" (127), đường kính vòng tròn tâm lỗ bulon 3 7/8" (98), đường kính lỗ bulon (4 lỗ) 5/8 (16)

+ Van F50, 50mm MMC-A (JIS), 2", đường kính ngoài 155mm (6.1"), đường kính vòng tròn tâm lỗ bulon 120mm (4.72"), đường kính lỗ bulon (4) 19 (0.75")

- Khối lượng:

+ Van "B", 2" (2318-2S-F316-BC): 14 lb. (6.35 kg)

+ Van Micro "B", 2" (2318-2S-FMS-BC): 13 lb. (5.9 kg)

+ Van Mini Micro "B", 1 1/2" (2318-2S-F316BC): 9 lb. (4.1 kg)

+ Van F50 MMC-A (JIS), 2": 19.8 lbs. (9 kg)

- Dãy áp suất: 150 psi (10 KG/cm2), kín khí ở 2 psi (0.14 KG/cm2)

7. Ống thước và đồng hồ đo áp suất khí trơ

- Ống thước nối

MMC sản xuất nhiều loại ống thước nối với các van chặn hơi, giúp dễ dàng thay đổi cho các ống thước sẵn có trên thước đo hàng loại kín hoặc giới hạn. Ngoài ra, các ống thước nối có thể chuyển đổi để dùng với các van chặn của các hãng thước khác, điều này cho phép các ống thước nối của MMC có thể được sử dụng với hệ van khác sẵn có trên tàu. Tất cả các ống thước nối đều được sản xuất và kiểm tra tại nhà máy nhằm đảm bảo điểm đọc 0 trên thước không thay đổi khi sử dụng với ống thước nối thay đổi

- Đồng hồ đo áp suất khí trơ

Áp suất khí trơ bên trong két chứa có thể được đo đạc dễ dàng bằng cách lắp đồng hồ đo áp suất kiểu di động model GVP vào van chặn hoặc vị trí đo trên đỉnh két. Đồng hồ đo áp suất seri GVP-75 có cơ cấu làm kín khí để ngăn chặn sự rò khí từ bên trong két ra ngoài. Đồng hồ có cơ cấu tiết lưu dạng trục vít tạo sự an toàn khi áp suất thay đổi đột ngột và phin lọc dạng lưới giúp ngăn chặn bụi bẩn ở đầu vào

- Thang đo: +2500 to -1000mm (nước)

- Độ chính xác: + /- 1.5% toàn thang đo

|

|

|

|

| Model "GVP-75" | For use on Vapor Lock Model. "B", "C", "D", "F" Series | View of fitting on Tank Gauging Station [Vapor Locks] Model. "C-50" |

| Model "GVP-75A" | For use on Vapor Lock Model. "A", "G65K80" | |

| Model "GVP-75NF" | For use on Vapor Lock Model. "ANK-52" Series | |

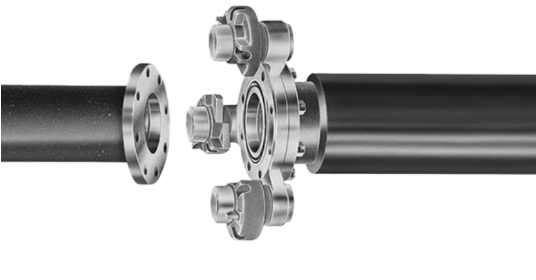

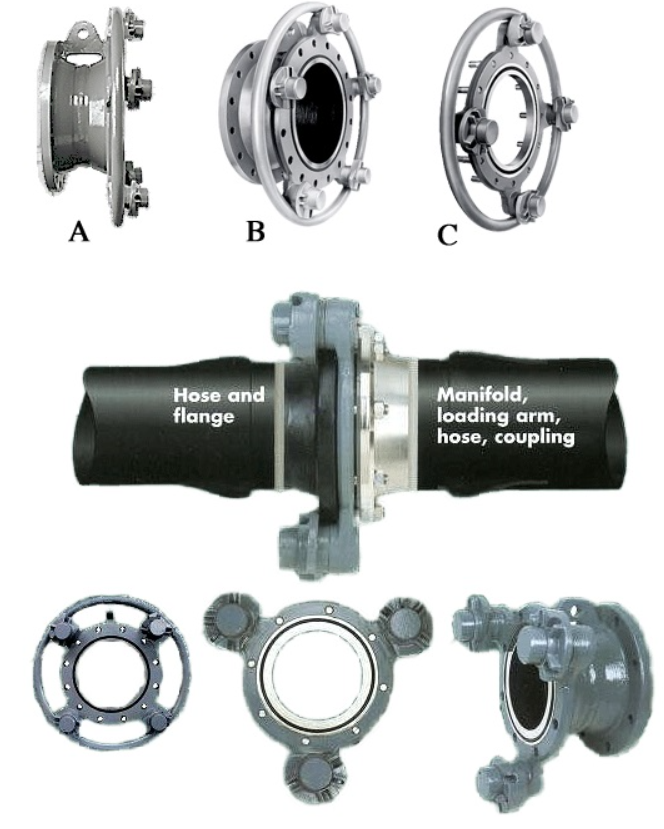

8. Khớp nối nhanh MMC

- Khớp nối nhanh với khóa an toàn kiểu bánh cốc

Thiết bị giúp kết nối nhanh và an toàn với nhiều ứng dụng đa dạng như: dùng cho ống nối trên bờ và phía kho cảng, dùng cho các ống góp, cần rót hàng, van… Các đầu nối (tùy thuộc vào đường kính) chứa từ 3-10 cam xoắn ốc. Mỗi một cam bánh cốc được khóa vị trí hoàn toàn độc lập, do đó cam không thể bị nới lỏng nếu không sử dụng dụng cụ mở khóa chuyên dụng. Bên dưới là khớp nối loại điển hình với 3 cam, giúp kết nối nhanh trong khoảng thời gian chưa đầy 1 phút

- Khớp nối nhanh loại tiêu chuẩn

Khớp nối nhanh loại tiêu chuẩn có thể là dạng dùng vít cấy, vành hàn và mặt trượt. Loại khớp nối dùng vít cấy được thiết kế để có thể bắt lên các mặt bích sẵn có bằng các vít cấy nhô ra ở mặt sau của khớp nối. Loại khớp nối kiểu vành hàn và mặt trượt thì được thiết kế để hàn trực tiếp vào ống, giúp tiết kiệm chi phí khi không dùng mặt bích phụ

- Khớp nối nhanh loại có van chặn hơi (dùng cho các tàu chở xăng dầu)

Khớp nối nhanh loại có chức năng thu hồi hơi dùng trong lĩnh vực hàng hải có thêm chốt định vị để ngăn chặn đường thu gom hơi được kết nối nhầm vào đường ống hàng. Chốt đặc biệt này phía mặt bích trên tàu chỉ có thể lắp vừa vào đầu nối đúng phía trên bờ. Khớp nối loại này được sơn màu vàng sáng giúp tránh nhầm lẫn

- Khớp nối đặc biệt (dùng cho các ống nổi ngoài khơi)

Khớp nối nhanh kiểu mặt bích ráp nối đặc biệt thích hợp dùng cho các ống nổi trong bơm chuyển ở lĩnh vực ngoài khơi. Cụm ống ráp nối được thiết kế dùng cho các đầu chuyển đổi ống góp khu vực kín, các điểm nâng ống và các khớp nối của các đầu giảm. cấu tạo có các tai móc đặc biệt và vòng bảo vệ cam giúp tăng cường khả năng chống ăn mòn trong lĩnh vực ngoài khơi. Ngoài ra, MMC còn đưa ra một loại khớp nối nhanh dùng vít cấy, có thể kết nối với các mặt bích sẵn có, hoặc loại có vít cấy đủ dài để nối các van bướm và đầu mặt bích của ống nổi

Trân trọng!

Công ty TNHH Kỹ thuật Hàng hải Phương Đông

+84 903 751396

+84 903 751396 phuongdong@otm.vn

phuongdong@otm.vn

.PNG)